Color conversion and ink saving for commercial Offset

The Challenge

Achieving consisten colors on different substrates using different printing processes are a challenge now a days. Most of the print ready files have a complicated source profile creates difficulty in consistent reproduction as well as to reproduce a similar between digital and conventional print machines.

The Solution

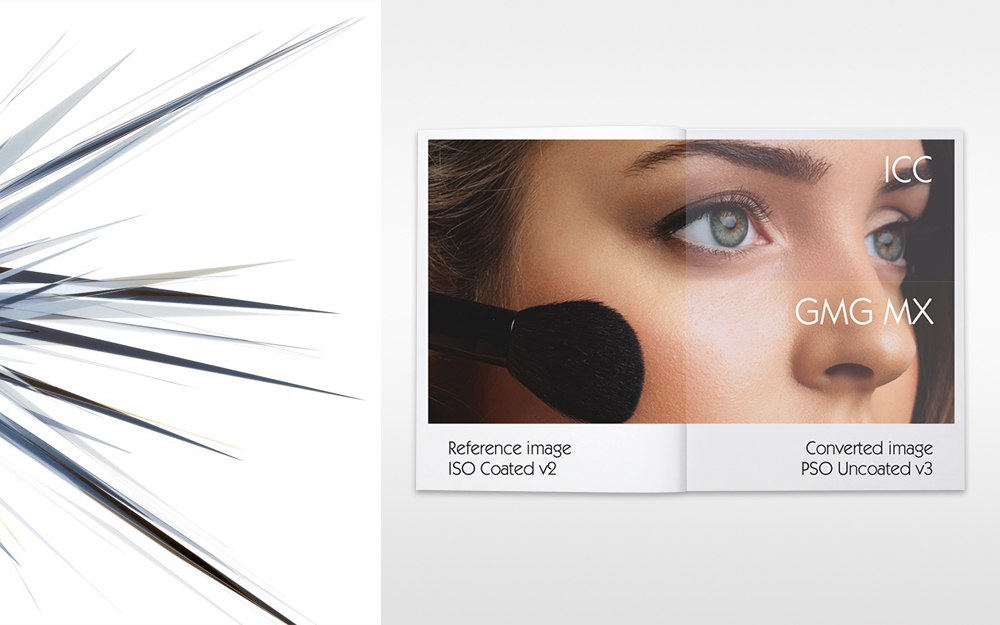

From source to target color space

Both large corporate businesses and small artisan brands have a global reach these days. This requires print projects to be produced in different countries and on different substrates. Color conversion of print data is therefore essential to achieve color consistent results. The industry-leading GMG MX Technology delivers high-quality color conversions. Sensitive color areas are stabilized and the black channel is retained. Consistent results across all printing processes and substrates are the result.

Keep colors consistent

As soon as print productions are outside industry standards such as ISO, PSO, GRACoL or SWOP, specific adjustments to the print data become unavoidable. The use of spot colors, special substrates or changing print conditions usually require individual profiling of the print data or the press. Tools such as GMG OpenColor or GMG SmartProfiler make the creation of individual profiles intuitive and simple

Process optimization with GMG InkOptimizer

Optimizing print data with under color removal saves up to 20% on ink. Crucially GMG InkOptimizer doesn’t only save money, it also stabilizes the printing process and enhances shadow detail. The software uses the most advanced conversion technology to increase the proportion of black and reducing color in neutral grey and shadow areas. The result is a more stable print run and increased output quality.

The Benefits

- Reliable color consistency throughout the production chain.

- Press-ready flattened and color managed PDFs.

- Smooth gradients, high detail in the shadows, bright and colorful images.

- Preservation of the black channel and pure colors.

- Consistent color appearance across different substrates.

- Simple configuration of typical tasks in day-to-day production.

- High performance through parallel job processing and automated workflows.

- Assured ink saving of 15-20%.

- Reduce setoff and press make ready time.